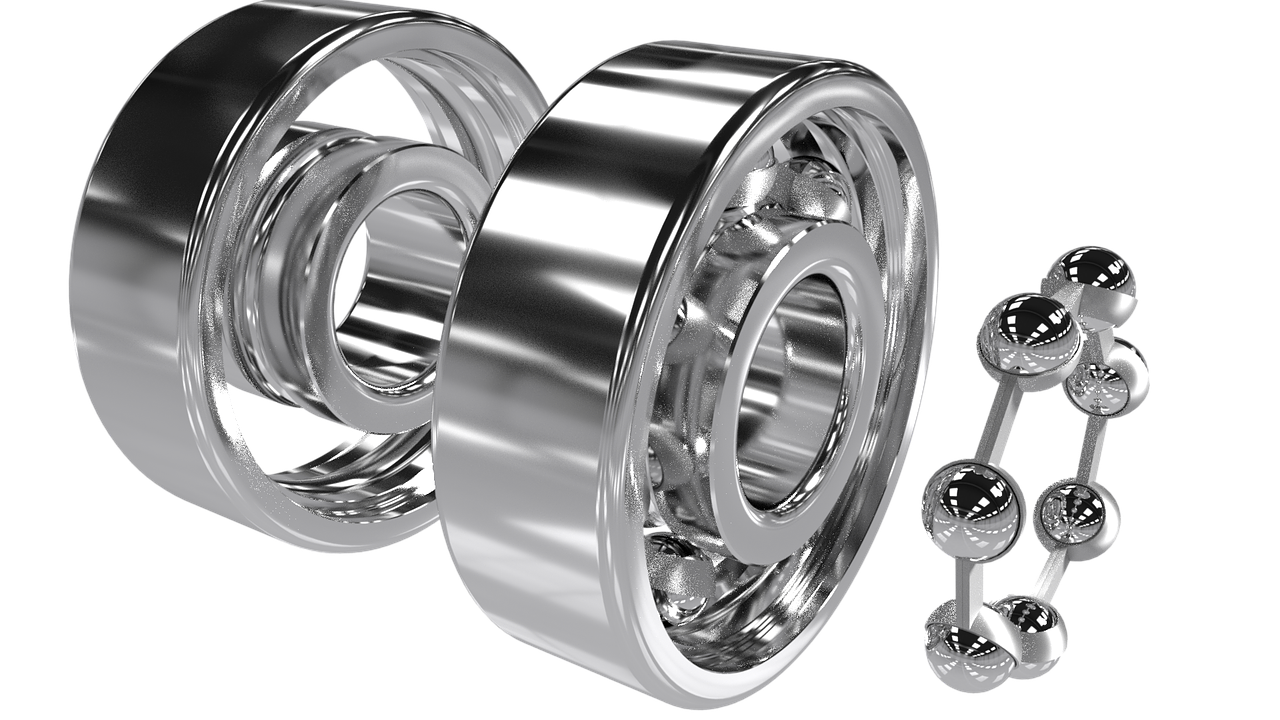

Bearings are used for many industrial applications and you can see them in so many machines. These are used for reducing friction and it will allow machine parts to move smoothly. There are many types of bearings with specific uses and some of them are listed in the article below.

The most common type of bearings you will come across is ball bearings and these are used in so many applications. You will find these in conveyor systems, motors and pumps. Then there are roller bearings that use cylindrical rollers instead of steel balls. These can be found in many heavy-duty applications such as mining equipment. This is because they are able to handle axial and radial loads. Sometimes common bearings will not be used in certain applications because there is very little space to operate in. In such circumstances, you will see needle roller bearings used.

A needle roller bearing is a thin long roller that is able to handle high radial loads. You can find these in different configurations such as machined needle roller bearings and combined needle roller bearings. These have a high load carrying capacity as there is a large contact area between the rollers and the raceway. There are downsides to the use of needle roller bearings as well because they are prone to misalignment more than the other types. And without proper lubrication, these can wear out very quickly.

You will find tapered roller bearings in automotive and industrial applications

These have two parts and this type of bearing is able to handle both axial and radial loads. You will also see spherical roller bearings that can handle both of these loads. These are used for heavy-duty applications and these are able to accommodate misalignment between the housing and the shaft. In applications where there is a large thrust load, you can use thrust bearings. You will see this in gearboxes.

Some of the configurations these will come in are needle, ball and roller. In applications where there is low friction, you can consider the use of sleeve bearings that is also known as bushings. These have a shaft and a metal sleeve and you can see this mainly in electric motors.

In aerospace equipment, magnetic bearings will be used

Unlike the traditional bearing, these use magnetic fields to rotate and levitate. It is not just steel that bearings are made of. There are ceramic bearings as well that are made of silicon nitride. And these are able to operate at very high temperatures and speeds. These are resistance to corrosion and wear. You can see the use of ceramic bearings in high performance applications.

In certain measuring equipment where high accuracy is needed, hydrodynamic bearings are used. These are used for low friction applications and the use of a fluid film allows for quiet operation. Instead of a fluid, a thin film of compressed air will be used to rotate the shaft of air bearings. These are used in low friction applications where a high level of accuracy is needed.

Sorry, the comment form is closed at this time.